French Training Ship 1896

French Training Ship of 1896

Historical Account of "BELEM"

Launched as a three masted Barque on the 10th June 1896, the "BELEM" was built by the Chantiers Dubigeon Co. of Nantes, France and made her maiden voyage to Montevideo on July 31st.

Originally built as a cargo vessel, she carried sugar from the West Indies and coffee from Brazil and French Guiana to her home port until, in 1914, she was sold to Hugh Grosvenor, Duke of Westminster to be renamed, re-rigged and used as a luxury yacht. She changed hands in 1921, was again renamed and re-rigged until 1949 when she was laid up at Cowes, Isle of Wight.

Purchased in 1951 by Count Vittorio Cini of Italy, she was primarily used as a training ship until being laid off Venice in 1965, being economically too old for further use.

Eventually, in 1979 she was towed back to France where she was fully restored to her original condition as a training vessel.

General Specifications:

Length Overall -58.0 m Breadth amidships-8.8 m Mainmast height (above waterline)-34.0 m

GRT- 534 tons Displacement - 750 tons Draft - 3.6m Sail number-22

Motive Power- 2 John Deere 6135AFM diesel engines , 575 HP each (fitted 2013)

Crew : 16 permanent deck incl. Master, Ch.Off, 2 Lieutenants. 1 ch.eng and 4 petty officers incl cook, carpenter and Boatswain. In addition, there are 48 places for trainees.

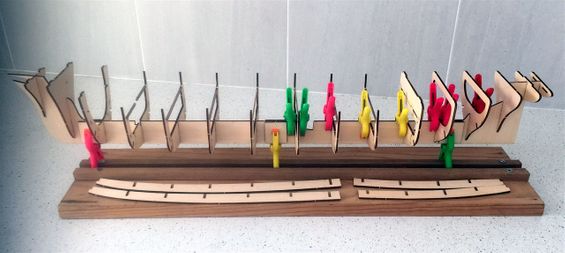

Framing under way

Opening up this kit is a joy to behold! Every section of the kit is is individually sealed in fine plastic and the metal parts convenienly separated in divided compartments.

Frames described

The uniqueness and accuracy of the frames is shown here. Apart from Nos 1 and 2 frames, each of the others are built up in three pieces with most also fitted with a cross bar.

The laser cut parts are excellent in strength and precision. It is, however, most important to ensure each is glued in and carefully checked with a set square to ensure they are at right angles to the keel.

Apart from frames 1 and 2, the rest of the frames are lazer cut into at least 4 if not 5 separate parts. These were glued and laid out to dry overnight before being set in their appropriate positions.

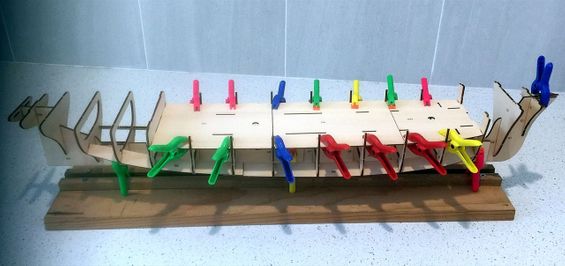

Frames in place

The emphasis is very much on checking and re-checking to ensure the frames are at right angles. All the parts fitted perfectly in their positions although frames 15 an 16 at the extreme of the stern were difficult to ensure drying maintained their position.

As can be seen, the clamps was put to use wherever necessary. The photo shows four sections lying in wait to be fitted into the matching grooves(notches) in the frames on each side. These ensure the strength and accuracy of the framing.

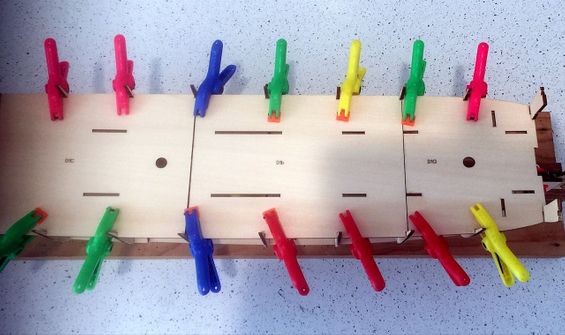

Aerial view of frames

Not only does the view do the job of double checking but also gives an idea of the length of the model. Including the bowsprit and stern fittings, it is 807 mms long.

Main decking in place

The main decking was lazer cut into 3 sections all which rested on the thwartship 3x2 mms timbers attached to the frames. With care, they fitted perfectly and were held in position using the ever useful plastic clamps

Overview of the angled clamps

The clamps are shown here, carefully placed/angled so as to grip the underside timber supports.

Here is a view of a section of the angled clamps so they can grip the timbers to decking. It may be noted that the temporary cradle cannot be used as the keel exposure is too small to allow for stabiity.

Meantime the clamps secured to the keel allow for some access to the model for this work.